The Impact of Commercial Deck Oven Uniformity on Bread Quality – Key Factors Analysis

In the baking industry, oven uniformity directly determines the bread's color, expansion, and internal structure. However, factors affecting uniformity go beyond just temperature control accuracy. The oven chamber material, heating element layout, and insulation design all play a crucial role. Below are the four key factors that determine oven uniformity:

Oven Chamber Material – The Advantages of Aluminized Steel

The material of the oven chamber directly impacts heat reflection and temperature stability. Using aluminized steel as the inner lining enhances heat radiation uniformity and reduces localized overheating. Compared to traditional stainless steel, aluminized steel offers superior thermal conductivity, ensuring even browning of the bread surface and minimizing temperature fluctuations.

Oven Chamber Thickness – Precision Design at 1.0–1.2mm

The thickness of the deck oven chamber affects heat stability and thermal inertia. A chamber wall that is too thin leads to heat loss and increased temperature fluctuations, while one that is too thick may reduce heating efficiency and increase energy consumption. After extensive testing, we have determined that a thickness of 1.0–1.2mm maintains heat stability while allowing the oven to respond quickly to temperature adjustments, further optimizing baking uniformity.

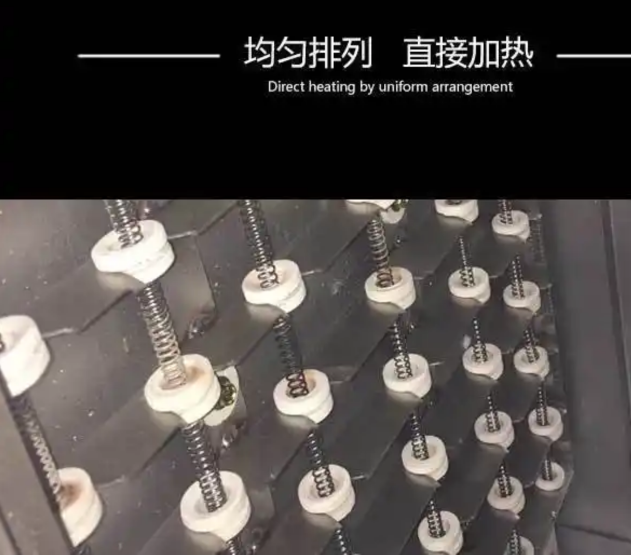

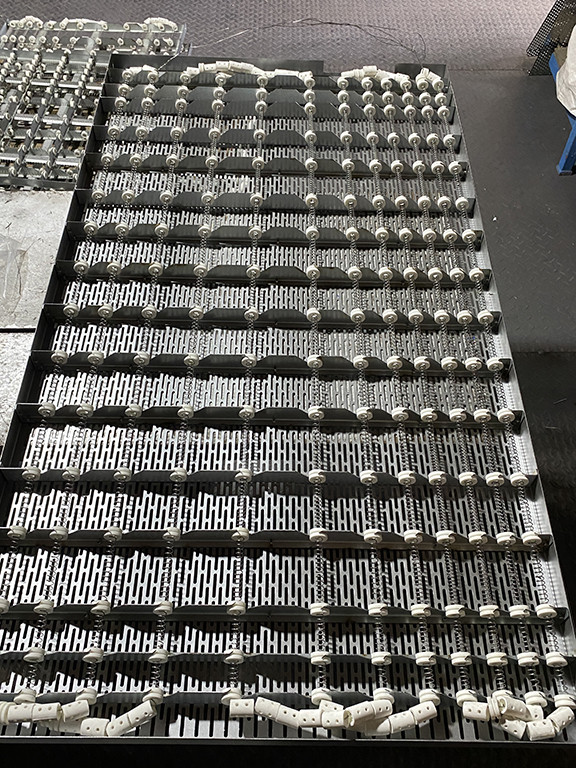

Non-Uniform Heating Element Layout – Scientific Heat Distribution

Many manufacturers in the baking equipment industry use evenly distributed heating elements, assuming this provides more balanced heating. However, based on years of experience, we have adopted a non-uniform layout, where each row has a different arrangement, and even within a single row, the placement varies. This unique design allows the oven to distribute heat more precisely, preventing localized hot or cold spots and enhancing overall baking uniformity. Market validation over the years has shown that this design effectively improves baking results and reduces defect rates.

Standard Heating Element Layout in Most Ovens

Sambake Deck Oven Heating Element Layout

Efficient Insulation – The Role of Thermal Insulation Cotton

The deck oven's insulation system not only affects energy consumption but also plays a decisive role in temperature uniformity. High-efficiency thermal insulation cotton reduces heat loss from the chamber, improves temperature retention, and prevents external temperature fluctuations from impacting the baking process. A well-designed insulation system also prevents localized overheating of the oven walls, ensuring a more stable and uniform internal temperature.

Oven uniformity is not solely dependent on precise temperature control systems but also on chamber material, thickness, heating element layout, and insulation design. Through scientific structural optimization, Sambake deck ovens create a more stable baking environment, ensuring that each batch of bread achieves the ideal baking results. Continuous technological innovation has given us a unique advantage in the industry and earned us high recognition from our customers.